Finite element analysis – Why you need it?

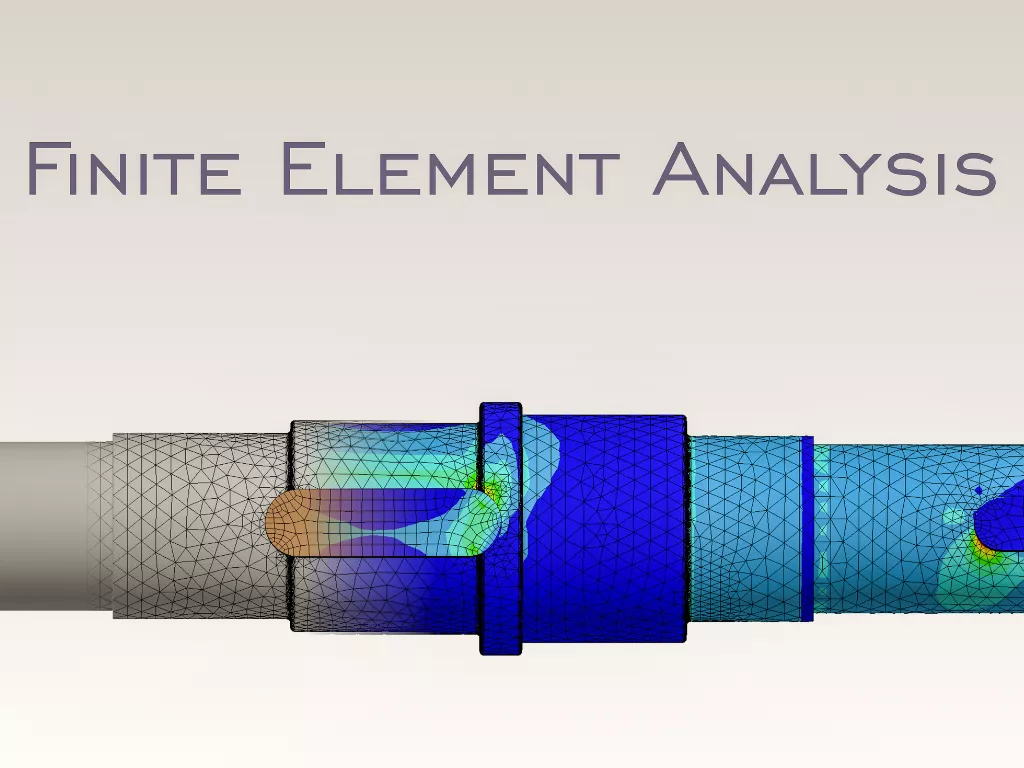

Traditional physical prototypes can be expensive and time-consuming. FEA creates a digital model of a product and applies various loads and conditions to simulate real-world performance. This allows engineers to identify weak points, optimize designs, and test countless variations virtually.

FEA software integrates seamlessly with Computer-Aided Design (CAD) tools. This creates a digital thread, where design changes made in CAD automatically update the FEA model, fostering a more efficient and digitalized workflow.

FEA eliminates the need for multiple physical prototypes. Engineers can virtually test and refine designs iteratively, identifying and fixing issues early. This significantly reduces the time needed for physical testing and redesigns, accelerating the entire product development cycle. With a shorter design cycle thanks to FEA, organizations can bring products to market quicker. This allows them to capitalize on market opportunities faster and gain a competitive edge.

In essence, FEA acts as a powerful digital testing lab, enabling organizations to iterate, optimize, and validate designs efficiently. This translates to a more streamlined product development process, ultimately leading to faster time to market and a significant boost to digitalization efforts.

In this webinar, we covered various aspects related to Finite Element Analysis (FEA) and its applications.

It began with an introduction to material strength in solids and the Finite Element Method (FEM). The significance of FEA in solving complex engineering problems was emphasized, along with the discretization of continuous domains into finite elements. The role of elements and nodes in meshing was discussed.

The session highlighted why FEA is essential, especially considering the limitations of analytical methods. Digitalization using FEA was explored, showcasing its impact on engineering design and analysis. Specific applications in the medical domain, such as implant design and biomechanics, were presented.

Modes of heat transfer and non-dimensional numbers were also covered. A case study on thermal analysis demonstrated practical FEA implementation. Overall, the webinar provided valuable insights into FEA’s role in modern engineering practices.

This webinar was presented by Decos, a cutting-edge technology services partner ready to meet your diversified needs in the healthcare domain.

If you have any questions about this webinar or wish to seek advice on FEA project, please contact Devesh at devesh.agarwal@decos.com

We would love to discuss it with you!

Discover more

Cloud Computing Trends in Healthcare: IoMT, AI, and Blockchain Integration

Identifying, prioritizing, and controlling use-related risks in medical devices